Shielded Drag Chain Cable

The conductor is composed of multiple strands of ultra-fine twisted oxygen-free copper wire, with a specially modified PVC or PUR sheath, which can withstand more than 5 million bending times and is wear-resistant and oil-resistant. Its tinned copper wire braided shielding layer has a braiding density of ≥95%, which effectively resists electromagnetic interference and ensures accurate signal transmission in complex electromagnetic environments.

CRIA 0003-2016 Special Cables for Industrial Robots

TICW 21 Flexible Cables for Industrial Robots

2 PfG 2577/08.16 Cable Application Requirements for Robot Systems

Product Code | Product Specification | Insulation Diameter (ømm) | Reference Outer Diameter (ømm) | Inner Conductor DC Resistance (Max.Ω/km@20°C) |

HLFL-HOP30S.02.05 | 2×0.5mm² (20AWG) | 1.65 | 5.4 | 34.6 |

HLFL-HOP30S.03.05 | 3×0.5mm² (20AWG) | 1.65 | 5.9 | 34.6 |

HLFL-HOP30S.04.05 | 4×0.5mm² (20AWG) | 1.65 | 6.3 | 34.6 |

HLFL-HOP30S.05.05 | 5×0.5mm² (20AWG) | 1.65 | 6.7 | 34.6 |

HLFL-HOP30S.06.05 | 6×0.5mm² (20AWG) | 1.65 | 7.4 | 34.6 |

HLFL-HOP30S.08.05 | 8×0.5mm² (20AWG) | 1.65 | 8.8 | 34.6 |

HLFL-HOP30S.02.075 | 2×0.75mm² (19AWG) | 1.90 | 5.9 | 27.4 |

HLFL-HOP30S.03.075 | 3×0.75mm² (19AWG) | 1.90 | 6.4 | 27.4 |

HLFL-HOP30S.04.075 | 4×0.75mm² (19AWG) | 1.90 | 6.9 | 27.4 |

HLFL-HOP30S.05.075 | 5×0.75mm² (19AWG) | 1.90 | 7.4 | 27.4 |

HLFL-HOP30S.06.075 | 6×0.75mm² (19AWG) | 1.90 | 7.9 | 27.4 |

HLFL-HOP30S.08.075 | 8×0.75mm² (19AWG) | 1.90 | 9.6 | 27.4 |

HLFL-HOP30S.02.10 | 2×1.0mm² (18AWG) | 2.2 | 6.5 | 21.8 |

HLFL-HOP30S.03.10 | 3×1.0mm² (18AWG) | 2.2 | 7.1 | 21.8 |

HLFL-HOP30S.04.10 | 4×1.0mm² (18AWG) | 2.2 | 7.8 | 21.8 |

HLFL-HOP30S.05.10 | 5×1.0mm² (18AWG) | 2.2 | 8.2 | 21.8 |

HLFL-HOP30S.06.10 | 6×1.0mm² (18AWG) | 2.2 | 9.1 | 21.8 |

HLFL-HOP30S.08.10 | 8×1.0mm² (18AWG) | 2.2 | 10.8 | 21.8 |

HLFL-HOP30S.02.15 | 2×1.5mm² (16AWG) | 2.5 | 7.2 | 13.7 |

HLFL-HOP30S.03.15 | 3×1.5mm² (16AWG) | 2.5 | 7.7 | 13.7 |

HLFL-HOP30S.04.15 | 4×1.5mm² (16AWG) | 2.5 | 8.5 | 13.7 |

HLFL-HOP30S.05.15 | 5×1.5mm² (16AWG) | 2.5 | 9.2 | 13.7 |

HLFL-HOP30S.06.15 | 6×1.5mm² (16AWG) | 2.5 | 10.1 | 13.7 |

HLFL-HOP30S.08.15 | 8×1.5mm² (16AWG) | 2.5 | 12.0 | 13.7 |

HLFL-HOP30S.02.25 | 2×2.5mm² (14AWG) | 3.0 | 8.2 | 8.62 |

HLFL-HOP30S.03.25 | 3×2.5mm² (14AWG) | 3.0 | 8.8 | 8.62 |

HLFL-HOP30S.04.25 | 4×2.5mm² (14AWG) | 3.0 | 9.8 | 8.62 |

HLFL-HOP30S.05.25 | 5×2.5mm² (14AWG) | 3.0 | 10.8 | 8.62 |

HLFL-HOP30S.08.25 | 8×2.5mm² (14AWG) | 3.0 | 14.2 | 8.62 |

HLFL-HOP30S.03.40 | 3×4.0mm² (12AWG) | 3.8 | 10.9 | 5.43 |

HLFL-HOP30S.04.40 | 4×4.0mm² (12AWG) | 3.8 | 12.3 | 5.43 |

HLFL-HOP30S.05.40 | 5×4.0mm² (12AWG) | 3.8 | 13.6 | 5.43 |

Product Model: HLFL-HOP30S

Product Performance:

Inner Conductor: VDE 0295 class 6 / IEC 60228 class 6 multi-strand stranded bare copper conductor

Insulation: Special elastomer material

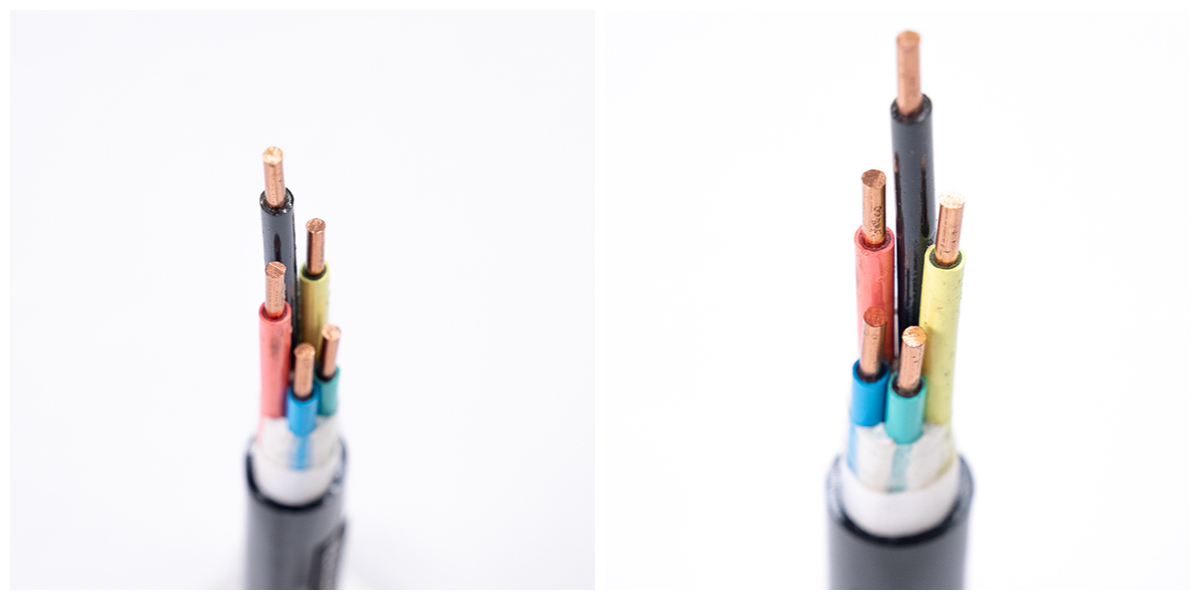

Insulation Marking: Black insulated wire cores with numerical numbering [1, 2, 3...]; Cables with 3 cores or more are equipped with 1 yellow/green grounding protection core wire (*Note 2)

Shielding: Tinned copper wire braiding

Outer Sheath: 80℃ elastic lead-free heat-resistant PVC compound

Outer Sheath Color: Black (BK, RAL9005), orange (OG, RAL2003) with matte finish

Drag Chain Service Life: >20 million bending cycles

Special Performance: High flexibility, wear resistance, drag resistance, oil resistance

Working Voltage: 300V

Minimum Bending Radius:

Mobile Installation: 7.5×D

Fixed Installation: 4×D

Working Temperature:

Mobile Installation: -5℃~80℃

Fixed Installation: -40℃~80℃

Flame Retardant Performance: IEC60332-1

No Harmful Substances: RoHS

Packaging and Shipping

![600V80 ultra-high flexible power drag chain cable [shielded type]](https://cdn.hualingcable.com/cdn/ff/PYiHqanIWpLRg8kwwC4f4VwKLQka3XVnbZhupDJ6h38/1752619063/public/2025-07/6.2_3.jpg)

![600V80 ultra-high flexible power drag chain cable [shielded type]](https://cdn.hualingcable.com/cdn/ff/dxwWqlUBfkFrKNLpGCR5bAnE-l0HvAFbUvJ5z6UKtwM/1752619063/public/2025-07/8.1.jpg)

![600V80 ultra-high flexible power drag chain cable [shielded type]](https://cdn.hualingcable.com/cdn/ff/J8zQPFEOLIWcQC3kRAeCSBI_mMyhVzJu2XUZwl8bTJ0/1752619063/public/2025-07/8.2.jpg)