Mineral Fire Resistant Cable

Super fire resistance: Continuous power supply for 3 hours in 950℃ flames, passed the highest level test of BS6387

Flexible structure: The bending radius is only 6-10D, and the installation convenience is improved by 50%

Safe and environmentally friendly: Halogen-free combustion, light transmittance>60%, avoiding secondary damage

High efficiency and durability: The current carrying capacity is 20% higher than that of ordinary cables, and the service life exceeds 100 years

Multiple protection: Copper sheath waterproof + mineral layer impact resistance, suitable for extreme environments such as nuclear power plants

Product Description

Executive Standard

![Mineral Fire Resistant Cable Mineral Fire Resistant Cable]() Model and Name

Model and Name

Model | Rated Voltage | Name |

YTTW | 0.6/1kV | Copper Conductor, Corrugated Copper-Sheathed Inorganic Mineral Insulated Cable |

YTTWV | 0.6/1kV | Copper Conductor, Corrugated Copper-Sheathed Inorganic Mineral Insulated Cable with PVC Sheath |

WD-YTTWY | 0.6/1kV | Copper Conductor, Corrugated Copper-Sheathed Inorganic Mineral Insulated Cable with Halogen-Free Low-Smoke Polyolefin Sheath |

Cable Specifications

Product Characteristics

Rated voltage: U₀/U is 0.6/1kV

The maximum long-term allowable operating temperature of the cable conductor is 90°C, and the maximum short-circuit temperature (with a maximum duration of 5s) is 250°C.

Bending radius: The minimum bending radius of the cable during installation is shown in the table below:

Item | Minimum Bending Radius During Cable Installation |

D ≤ 12 | 6D |

12 < D ≤ 20 | 10D |

20 < D ≤ 40 | 15D |

D > 40 | 20D |

※ Note: D refers to the cable outer diameter. | - |

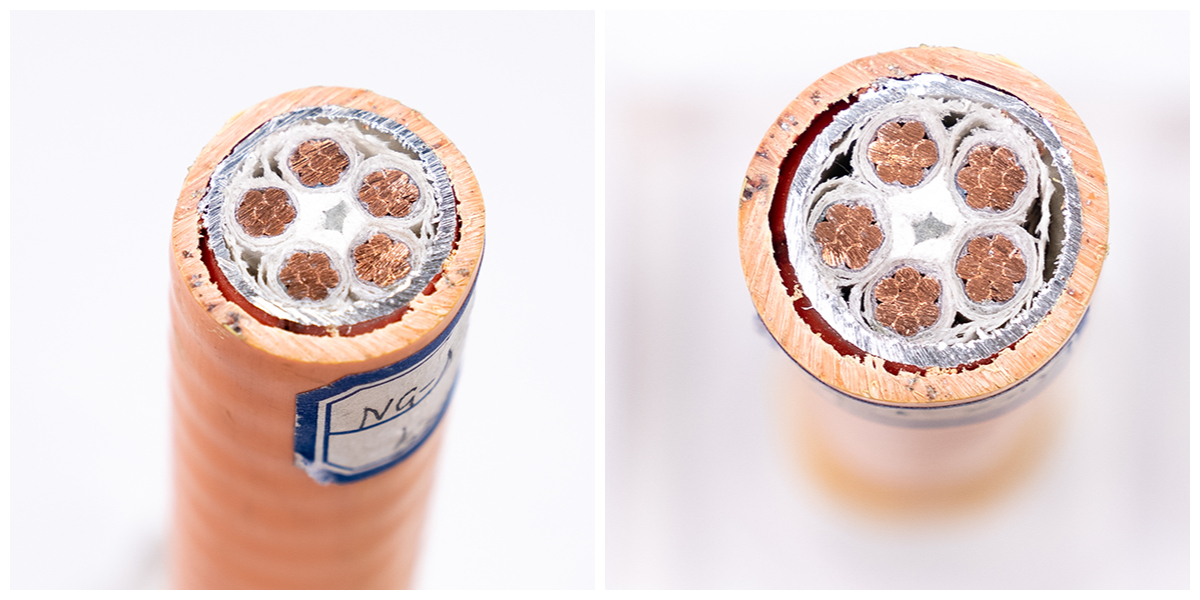

Structural Diagram

Single-core Cable (YTTW): Corrugated Copper Sheath, Protective Layer, Copper Conductor, Inorganic Insulation

Single-core Cable (WD-YTTWY): Corrugated Copper Sheath, Protective Layer, Copper Conductor, Inorganic Insulation, Outer Sheath

Multi-core Cable (YTTW): Copper Conductor, Inorganic Insulation, Inorganic Filling, Protective Layer, Corrugated Copper Sheath

Multi-core Cable (WD-YTTWY): Copper Conductor, Inorganic Insulation, Inorganic Filling, Protective Layer, Corrugated Copper Sheath, Outer Sheath

Performance Parameters

(Applies to YTTW and WD-YTTWY)

Item | Unit | Index |

DC resistance of conductor (at 20°C), ≤ | Ω/km | Complies with GB/T 3956-2008 |

Insulation resistance | MΩ | The product of the cable's insulation resistance (MΩ) and cable length shall not be less than 100 Ω·km; when the cable length is less than 100m, the measured insulation resistance shall not be lower than 1000 MΩ |

AC voltage | - | 3.5kV/5min at 50Hz AC, no breakdown or alarm shall occur to the cable |

Fire resistance (in accordance with BS 6387) | - | - Under a flame of 950°C ± 40°C: continuously energized for 180min, the circuit maintains integrity (Category C); - Under a flame of 650°C ± 40°C: continuously energized for 150min, then subjected to 15min water spray, the circuit maintains integrity (Category W); - Under a flame of 950°C ± 40°C: subjected to 15min mechanical impact, the circuit maintains integrity (Category Z) |

Packaging and Shipping