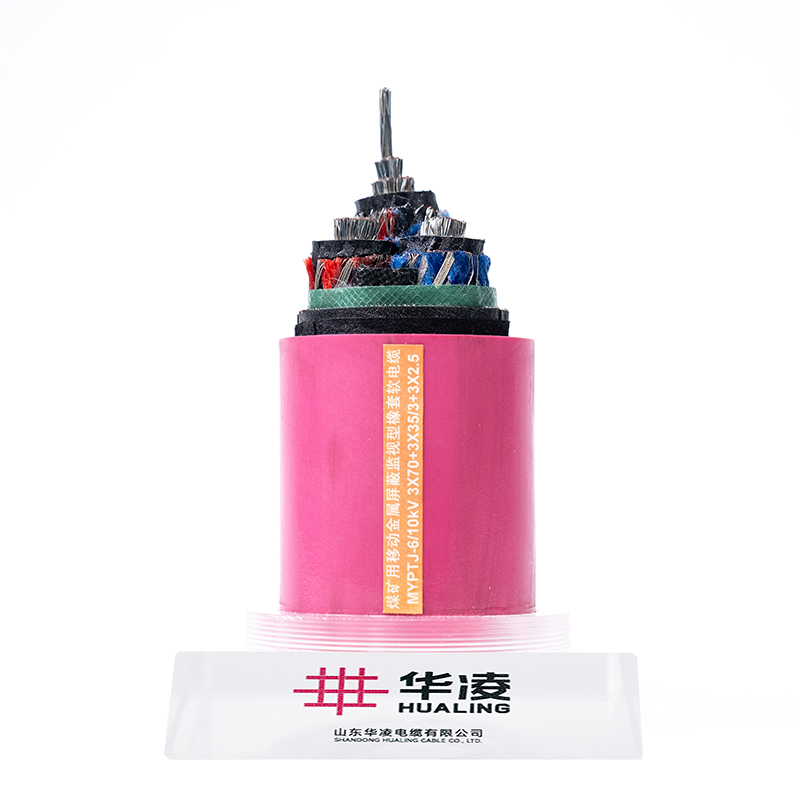

Coal Mine Shielded Monitoring Flexible Cable

High voltage safety: 8.7/10kV withstand voltage level, meeting the needs of underground high-power equipment

Double shielding: copper wire braiding + aluminum foil composite shielding, anti-electromagnetic interference ability increased by 60%

Real-time monitoring: integrated monitoring core, insulation fault warning response time <0.1 second

Super strong protection: chloroprene rubber sheath is wear-resistant and corrosion-resistant, with a service life of 2 times that of ordinary cables

Flexible movement: bending radius ≤6D, suitable for high-frequency mobile working conditions of coal mining machines

Product Description

This cable is mainly used for transmitting control, measurement signals, etc. It is suitable for long-distance operation, control signals, and protection measurement circuits in mainstream and AC 50Hz systems with a rated voltage of 450/750V, 600/1000V, and below. As a connecting wire between various electrical instruments and automated instrumentation devices, it plays a role in transmitting various electrical signals and ensuring the safe and reliable operation of the system.

Executive Standards

• MT/T 386-2011 Test Methods and Judgment Rules for Flame Retardant Performance of Mining Cables for Coal Mines

• Q/HL0100HLT058-2021 Mining Control Cables for Coal Mines with Rated Voltage 450/750V and Below

Technical Parameters

• Withstands a 3kV/5min power frequency AC withstand voltage test without breakdown.

• Elongation under load is not greater than 175%, and permanent deformation after cooling is not greater than 15%.

• Scorching of the sample shall not exceed the range beyond 50mm to 540mm from the lower edge of the upper clamp.

• Maximum charring shall not exceed 2.5m upward from the bottom edge of the burner.

• Minimum light transmittance is 60%.

• After 90 minutes of fire supply plus 15 minutes of cooling, the 2A fuse does not blow and the indicator light does not go out.

• PH weighted value ≥ 4.3; conductivity weighted value ≤ 10μS/mm.

Product Characteristics

• The long-term allowable operating temperature of the cable is 70℃.

• Minimum bending radius of the cable during laying:

◦ For cables without an armor layer, it shall not be less than 10 times the outer diameter of the cable.

◦ For cables with an armor or copper tape shielding structure, it shall not be less than 12 times the outer diameter of the cable.

◦ For flexible cables with a shielding structure, it shall not be less than 6 times the outer diameter of the cable.

• The laying temperature of the cable shall not be lower than 0℃.

• Rated voltage Uo/U is 450/750V.