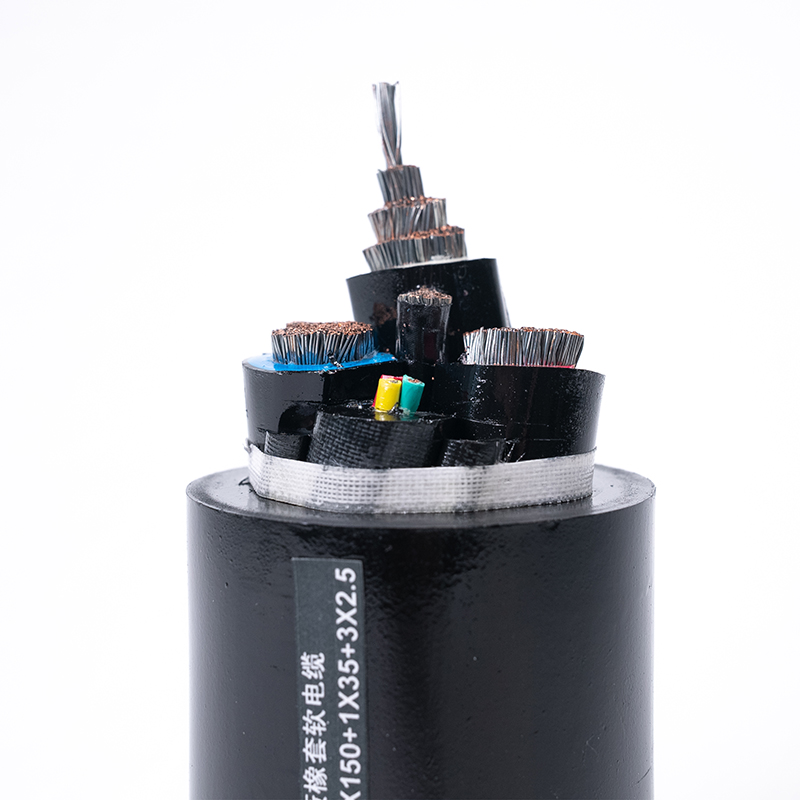

Flexible Cable for Mining Coal Machine

Super strong and tough: multiple strands of fine copper wires are twisted, with a bending radius of ≥8D, which can adapt to the frequent movement of coal mining machines;

Reliable pressure resistance: 3.3kV insulation thickness is optimized and passed the GB/T 12972 mining standard test;

Anti-damage protection: The chloroprene rubber sheath is tear-resistant and oil-resistant, with a lifespan of 100,000 bends;

Safety and flame retardancy: Flame retardancy grade B, stable operation in extreme environments of -40℃~90℃;

Efficient power transmission: Low impedance design, the current carrying capacity is 12% higher than similar products.

Product Description

It is suitable for power connection of underground coal mining machines and similar equipment.

Executive Standards

• MT818.2-2009 Mining Cables for Coal Mines — Part 2: Flexible Cables for Coal Mining Machines with Rated Voltage up to 1.9/3.3kV

• MT818.3-2009 Mining Cables for Coal Mines — Part 3: Shielded, Monitored and Reinforced Flexible Cables for Coal Mining Machines with Rated Voltage up to 1.9/3.3kV

• MT818.4-2009 Mining Cables for Coal Mines — Part 4: Metal-Shielded Flexible Cables for Coal Mining Machines with Rated Voltage up to 1.9/3.3kV

Technical Parameters

• Conductor DC resistance: Complies with the provisions of MT818 standard.

• Heat extension: Air temperature 250±3℃, loading time 15min, mechanical stress 20N/cm², elongation under load ≤175%, permanent deformation after cooling ≤15%.

• Withstand voltage:

◦ For cables with rated voltage 0.66/1.14kV: Power core 3.7kV, control core 1.5kV; no breakdown occurs after applying voltage for 5min.

◦ For cables with rated voltage 1.9/3.3kV: Power core 6.8kV, control core 1.5kV; no breakdown occurs after applying voltage for 5min.

• Single vertical burning: The distance between the lower edge of the upper clamp and the starting point of upper charring is greater than 50mm; the distance between the lower edge of the upper clamp and the starting point of lower charring is not greater than 540mm; burning drips during the test do not ignite the filter paper under the sample.

• Burning under load condition: When 5 times the rated current is applied and the conductor temperature rises to 205℃±5℃, the burning time is 1min, the afterflame time is less than 4min, and the charring length is less than 150mm.

• Bundled burning:

◦ If the maximum core cross-sectional area of the power cable is 50mm² or above, it complies with Class A/F specified in GB/T 18380.32-2022.

◦ If the maximum core cross-sectional area of the power cable is below 50mm², it complies with Class B specified in GB/T 18380.34-2022.

Product Characteristics

• Rated voltages: 0.38/0.66kV, 0.66/1.14kV, 1.9/3.3kV.

• The minimum bending radius of the cable is 6 times the cable diameter.

• The ground core of the cable shall be well grounded.

• Delivery length: The cable is delivered according to the length agreed by both parties, with a negative deviation in length measurement not exceeding 0.5%.

Packaging and Shipping