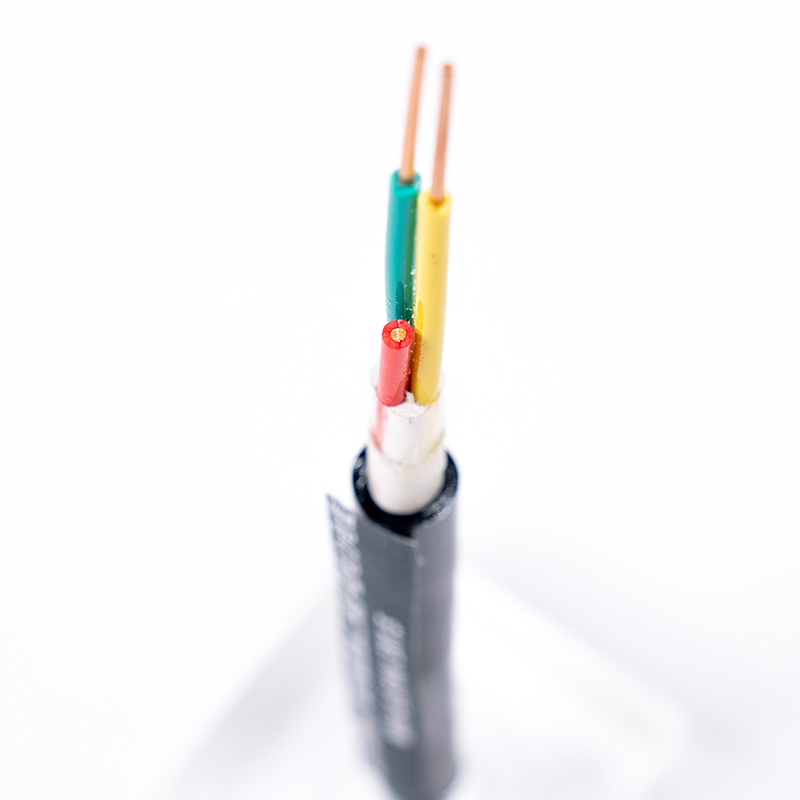

Mining PVC Insulated Power Cable

Flame retardant and safe: in compliance with MT 818.12 standard, self-extinguishing and low smoke in case of fire, ensuring safety underground;

Strong weather resistance: adapt to the humid and corrosive environment of mines, the sheath is oil-resistant and acid-resistant;

Mechanical protection: MVV22 steel belt armor design can withstand mechanical external forces and is suitable for complex laying;

Economical and practical: the cost is lower than that of cross-linked cables, maintenance is simple, and it is suitable for fixed laying scenarios;

Temperature stability: long-term working temperature is 70℃, short-circuit tolerance is 160℃, and reliability is high.

Product Description

Suitable for power transmission and distribution lines with a rated voltage of 8.7/10kV and below in underground coal mines. These power transmission cables are specially designed for harsh environments such as underground coal mines and are mainly used for power transmission in underground mining power equipment and distribution systems. They can operate safely in environments containing flammable and explosive media such as gas and coal dust.

Executive Standards

• MT818.11-2009 Cables for Coal Mines - Part 11: General Provisions for Power Cables with Rated Voltage of 10kV and Below for Fixed Laying

• MT818.12-2009 Cables for Coal Mines - Part 12: Polyvinyl Chloride Insulated Power Cables for Coal Mines with Rated Voltage of 1.8/3kV and Below

• MT818.13-2009 Cables for Coal Mines - Part 13: Cross-linked Polyethylene Insulated Power Cables for Coal Mines with Rated Voltage of 8.7/10kV and Below

Specifications and Models

Model | Meaning | Application Scenarios |

MVV | Mine-used (M), Polyvinyl chloride insulation (V), Polyvinyl chloride sheath (V) | Fixed laying, no special mechanical protection required (e.g., piped, 桥架) |

MVV22 | Mine-used, Polyvinyl chloride insulation, Polyvinyl chloride sheath, Steel tape armoring (22) | Direct burial laying or occasions requiring mechanical protection (e.g., underground roadways, soil) |

Specification Parameters

• Rated Voltage: 1.8/3kV (phase voltage 1.8kV, line voltage 3kV).

• Number of Cores: All 3-core (three-phase power systems are common in underground coal mines).

• Conductor Cross-Section: According to current-carrying capacity requirements, common cross-sectional specifications (mm²) include: 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240.

• Conductor Material: Copper conductors (T) are preferred for their good conductivity and strong corrosion resistance; aluminum conductors (L) can be used in some scenarios but must meet mechanical strength requirements.

Product Characteristics

1. Rated voltages include 0.6/1kV, 1.8/3kV, 3.6/6kV, 6/6kV, 6/10kV, and 8.7/10kV.

2. The ambient temperature during cable laying shall not be lower than 0℃. The minimum bending radius of the cable is 15 times the cable diameter.

3. The maximum rated operating temperature of conductors in polyvinyl chloride insulated cables is 70℃, and that of cross-linked polyethylene insulated cables is 90℃.

4. During a short circuit (with a maximum duration not exceeding 5 seconds), the maximum temperature of the cable conductor shall not exceed 160℃.

Packaging and Shipping